Core IQF Freezing Principle: Rapid Heat Removal and Ice Crystal Control Physics of Ultra-Rapid Freezing: Suppressed Ice Nucleation and Minimized Intracellular Damage IQF freezers work mainly because they pull heat away super fast, usually at rates ...

VIEW MORE

Understanding Blast Chiller Capacity: Matching GN Pan Volume to Daily Production Needs Calculating Daily Food Load Using GN Pan Equivalents and Peak Hour Demand Getting the right size blast chiller starts with figuring out how much food gets produc...

VIEW MORE

Verify Temperature Control and Calibration Why Consistent -18°C ±1°C Is Critical for Food Safety and Pathogen Inhibition Keeping freezers at exactly -18 degrees Celsius plus or minus one degree isn't just important it's absolutely es...

VIEW MORE

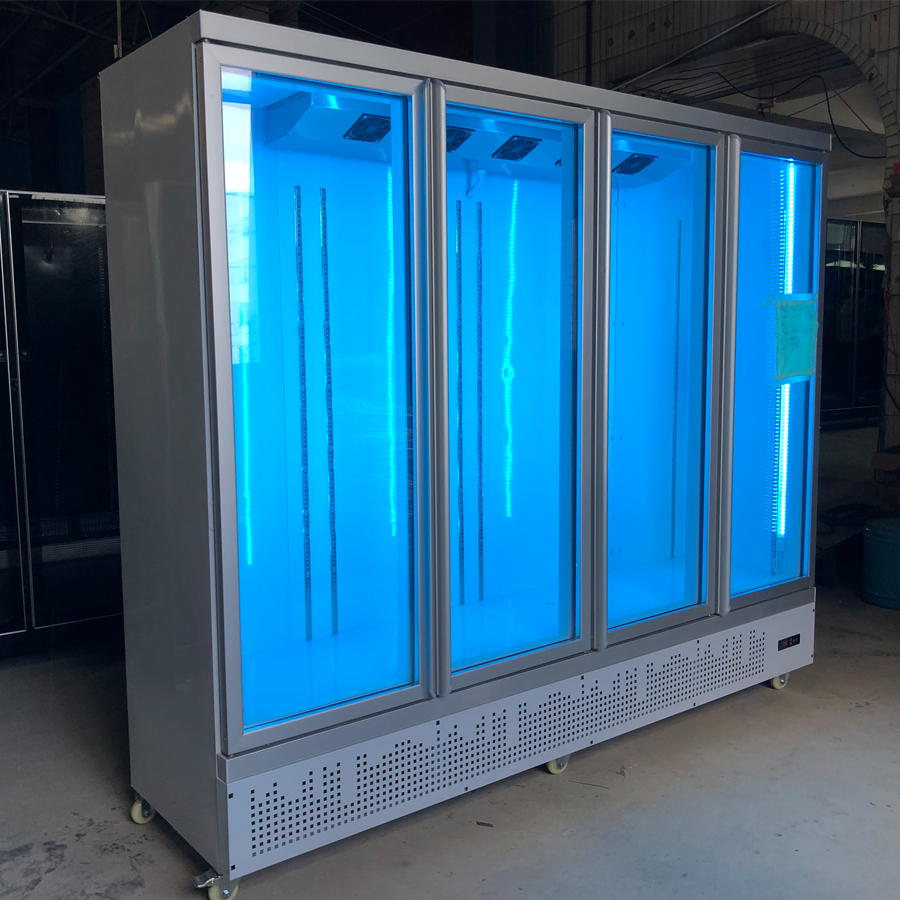

Optimizing Visibility and Customer Engagement Eye-Level Placement and Viewing Angle Science for Maximum Ice Product Appeal Putting an ice merchandiser around eye level, somewhere between 4.5 and 5.5 feet off the ground, makes products much easier t...

VIEW MORE

Variable Speed Compressor Technology for Adaptive Efficiency How Inverter-Driven Compressors Optimize COP and Reduce Peak Load Commercial fridge compressors with inverters can change their motor speeds based on what's actually needed for cooling ri...

VIEW MORE

Precise Temperature Control and Food Quality Preservation How Precise Temperature Control Preserves Food Quality Freezers that hit temperatures within a tight range of plus or minus 0.5 degrees Fahrenheit actually cut down on bacterial growth by ar...

VIEW MORE

High Failure Rates in Standard Commercial Freezers: A Costly Problem Most standard commercial freezers end up needing around two to three repairs every year because their compressors give out, door seals fail, or the defrost system acts up accordin...

VIEW MORE

Understanding the energy efficiency of ice production equipment Ice freezers today are getting much better at saving energy thanks to several key improvements. First off, they have these variable speed compressors that basically match their output ...

VIEW MORE

How a Commercial Refrigerator Maintains Food Safety Standards Commercial refrigerators keep food from going bad by holding temps under 40°F (about 4°C), which is what the USDA considers safe for slowing down bacteria growth. Some newer mode...

VIEW MORE

Temperature Stability: The Foundation of Drink Freshness in a Commercial Refrigerator Why Consistent Cooling Is Critical for Drink Preservation Beverage quality stays intact in commercial fridges when they keep things cool between about 34 and 38 d...

VIEW MORE

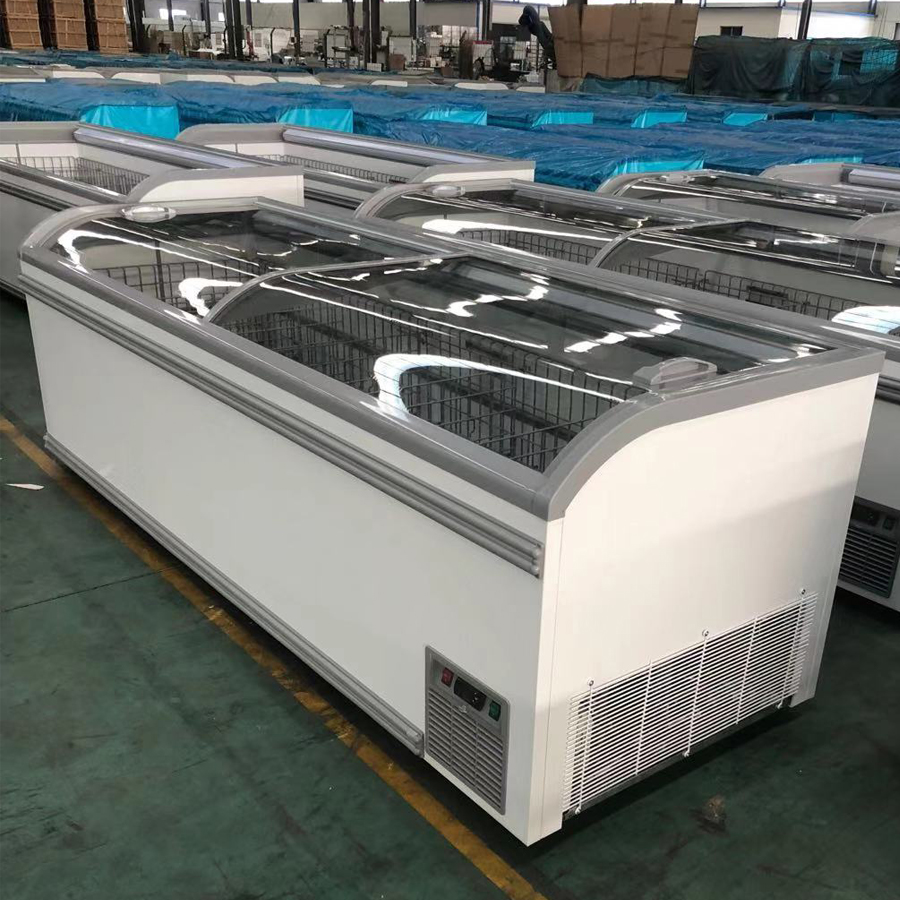

Temperature Control and Food Safety Features How Temperature Consistency Ensures Ice Quality and Safety Keeping ice merchandisers at exactly 41°F (about 5°C) stops ice from breaking down structurally and keeps microbes from getting in, whic...

VIEW MORE

Understanding the Flash Freezing Process and Its Impact on Nutrient Preservation Flash freezers use ultra-low temperatures (below -40°F) to freeze food within minutes, forming ice crystals smaller than 50 microns. This rapid process preserves c...

VIEW MORE