Understanding Key Types of Commercial Refrigerators

Selecting the right commercial refrigerator directly impacts operational efficiency and food safety. With distinct models designed for specific workflows, understanding core types ensures alignment with your business needs.

Reach-In Refrigerators: Ideal for High-Access Storage

These vertical units (typically 60"–72" tall) prioritize frequent ingredient retrieval in busy kitchens. Open-front designs allow servers to grab prepped items quickly during peak hours, making them essential for restaurants with limited back-of-house space.

Walk-In Coolers: Maximizing Storage Capacity for Large Operations

Walk-ins provide 150–1,500+ cubic feet of temperature-controlled storage, ideal for bulk ingredient preservation in grocery stores or banquet facilities. Their modular construction accommodates palletized deliveries, reducing restocking frequency by 40% compared to reach-in models.

Undercounter Refrigerators: Space-Saving Solutions for Compact Kitchens

With 24"–34" height profiles, these units fit beneath countertops in food trucks, coffee shops, and sushi bars. Dual-temperature models (35°F refrigeration + 0°F freezer compartments) help microbakeries manage pastry dough and finished goods in about 15 sq. ft.

Refrigerated Prep Tables: Streamlining Food Preparation Workflows

Combining 4°C–7°C chilled storage with stainless steel work surfaces, these hybrid units reduce cross-kitchen movement in delis and salad bars. A 72" model typically holds 18 hotel pans while providing 12 sq. ft. of prep space.

Comparative Analysis of Commercial Refrigerator Types by Use Case

| Type | Best Use Case | Energy Use (kWh/day)* | Space Efficiency |

|---|---|---|---|

| Reach-In | Line cook stations | 18–22 | Moderate |

| Walk-In | Bulk produce storage | 45–60 | Low |

| Undercounter | Limited-space operations | 8–12 | High |

| Refrigerated Prep Table | Assembly-line kitchens | 15–18 | Moderate |

*Based on EnergyStar 2023 averages for 34°F models

Matching refrigerator capacity and configuration to daily workflows prevents overinvestment while maintaining HACCP compliance. High-volume pizzerias might combine walk-ins (bulk cheese storage) with prep tables (topping assembly), while juice bars could optimize with undercounter units for produce and reach-ins for finished bottles.

Matching Refrigerator Type to Business Model and Operational Needs

Assessing Cold Storage Needs Based on Menu, Volume, and Workflow

When choosing a commercial fridge for a restaurant, there are basically three things to consider first: what kind of food gets made most often, how much stuff goes through each day, and how the kitchen actually operates. Places that deal with lots of fresh veggies, especially those salad bars everywhere these days, really need good humidity control around 85 to 90 percent relative humidity just to keep lettuce from wilting away. Burger spots that stack up hundreds of patties tend to care more about how fast they can move frozen meat into cold storage areas. Kitchens where inventory turns over quickly, maybe 70 percent or more every single day, generally need about 20 to 30 percent extra space beyond what they think they'll need because business tends to spike unexpectedly. Take pizza places for instance. A shop making 150 pizzas per day needs a reach-in cooler that can bounce back quickly after someone opens the door repeatedly throughout service hours, keeping temperatures between 34 and 38 degrees Fahrenheit even when staff is constantly grabbing ingredients.

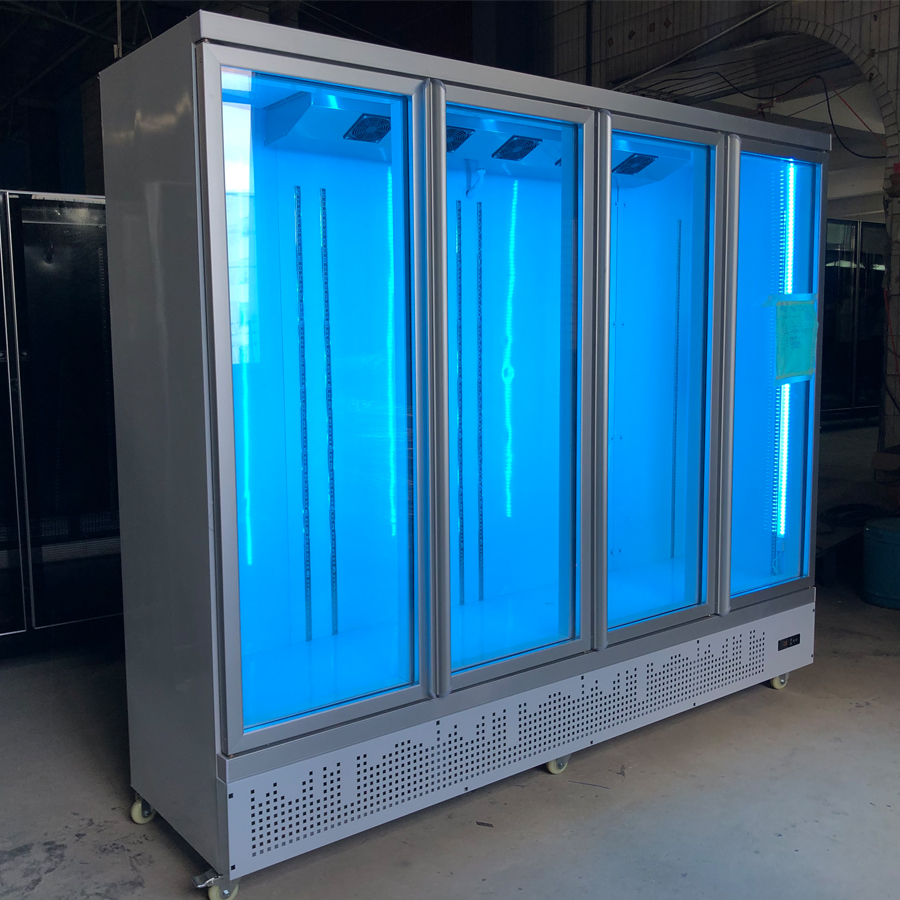

Use Cases for Food Trucks, Bars, Convenience Stores, and Restaurants

Most mobile food vendors go for vertical commercial fridges when space is tight. According to the Mobile Vending Association report from last year, about 78% choose models that are less than 35 inches wide. These compact units still manage to hold between 15 and 20 cubic feet of stuff, which is pretty impressive given the space constraints on wheels. For bars serving up those fancy craft cocktails, undercounter coolers become essential equipment. They need special compartments for storing bitters and keeping fresh garnishes at hand. The shelves in these units tend to be 25 to 40 percent narrower compared to regular fridge models. Convenience stores and other retail spots really get behind glass front merchandising coolers. Products displayed behind dual pane glass actually remain 2 to 3 degrees Fahrenheit cooler than what's found in standard displays. This temperature difference makes a real difference too, extending product freshness by around 18 extra hours according to research from the Cold Chain Council back in 2023.

Restaurant vs. Retail: Divergent Storage Demands and Solutions

Full service restaurants typically set aside around 60 to 70 percent of their refrigeration area for back of house food preparation, while retail bakeries put about 80% of their cooling power into those fancy pastry cases right where customers can see them, maintaining temperatures between 28 and 32 degrees Fahrenheit consistently. The difference in how these spaces are used affects energy consumption quite a bit. Restaurants generally run about 15 kilowatt hours per day for each linear foot of refrigeration equipment, whereas retail locations need roughly 22 kWh because they have all those lit up display cases. For hybrid setups such as ghost kitchens, operators frequently install commercial refrigerators with split systems, allocating approximately half (around 55%) for actual food prep work and the remaining 45% as staging areas. This arrangement helps manage both large batches of food production and timely deliveries without overcomplicating things.

Sizing and Space Planning for Optimal Kitchen Integration

Measuring Available Space and Clearance Requirements

Start by getting accurate measurements of the kitchen space. Take note of all three dimensions - length, width, and height. Don't forget those tricky spots where things get in the way, like ventilation ducts or electrical boxes sticking out from walls. When it comes to commercial fridges, they need about 2 to 3 inches behind them for proper air circulation, and around 3 feet in front so doors can open fully and workers have room to move around comfortably. Walk-in refrigeration units are even trickier space-wise. Most experts recommend setting aside roughly 10 to 15 percent extra floor area beyond what the unit itself takes up. This gives technicians enough breathing room during installation and future maintenance work. And let's face it, wrong measurements really hurt business owners' wallets too. According to industry research from LS-USA back in 2023, many restaurants end up spending around four thousand two hundred dollars on unexpected changes when their initial plans didn't account for these spatial requirements properly.

Calculating Required Cubic Feet Based on Daily Inventory Turnover

Match refrigerator capacity to your operation’s daily throughput using this formula:(Daily Inventory Pounds · 25) ÷ 1.5 = Minimum Cubic Feet Required

A sandwich shop processing 400 lbs daily needs 24 cu.ft., while a seafood restaurant stocking 800 lbs requires 48 cu.ft. Undersized units increase energy costs by 18% due to frequent door openings (Hauslane 2023).

Kitchen Layout Considerations for Efficient Refrigeration Placement

When arranging kitchen equipment, think about how staff actually move around during service hours. Refrigerators should be positioned so that prep tables sit close to where cooking happens, while those smaller undercounter models go right below the drink station area. Many chefs swear by something called the work triangle concept, where refrigeration units, cutting boards, and stoves form an efficient layout pattern. Some studies suggest this setup can cut down on unnecessary walking for kitchen staff by roughly 30%. And don't forget about heat! Putting fridge units too close to ovens makes them run significantly harder. We've seen compressors work about 27% extra hard when placed near hot appliances according to recent research from Putnam Farmhouse last year.

Evaluating Performance Features and Energy Efficiency

Temperature Control and Climate Class Ratings Explained

Commercial fridges keep specific temperature zones based on their climate class ratings like N, SN, ST etc., these ratings basically tell us what kind of humidity and heat levels they can handle. Fridges labeled as ST (sub-tropical) work fine even when there's full 100% humidity at around 38 degrees Celsius. Then we have the tougher ones marked as T (tropical) that actually function properly in hotter conditions reaching 40 degrees Celsius. These higher rated units are really important for commercial kitchens where the environment isn't always stable or controlled consistently.

| Climate Class | Ambient Temperature | Humidity Tolerance |

|---|---|---|

| N | 16–32°C | ≤ 65% |

| SN | 10–32°C | ≤ 85% |

| ST | 18–38°C | 100% |

Door Type, Seal Integrity, and Frequency of Access Impact

Glass-front doors enhance product visibility but lose 30–40% more cold air per hour compared to solid doors (Restaurant Equipment Study 2023). Establishments with high foot traffic should prioritize triple-pane glass or magnetic seals to minimize temperature fluctuations during frequent access.

Compressor Location and Its Effect on Cooling Efficiency

Top-mounted compressors reduce noise and improve airflow in undercounter models, while rear-mounted units in reach-in refrigerators require 6–8 inches of rear clearance for optimal heat dissipation. Poor ventilation increases compressor workload by 15–20%, accelerating wear.

Durability, Materials, and Resistance to High-Use Environments

Stainless steel exteriors and NSF-certified polyethylene interiors withstand daily sanitation and resist corrosion. Models with antimicrobial door handles reduce cross-contamination risks in high-volume kitchens, extending equipment lifespan by 3–5 years.

Energy Efficiency Ratings and Their Impact on Operating Costs

The Energy Efficiency Ratio (EER) measures cooling output per watt consumed, with ratings above 2.5 indicating high-efficiency commercial refrigerators. Units with ENERGY STAR certification use 40% less energy than standard models, translating to $300–$500 annual savings for mid-sized restaurants according to 2024 refrigeration cost analyses.

Installation, Compliance, and Total Cost of Ownership

Ventilation, electrical, and flooring requirements for safe installation

Getting things installed right means following certain mechanical rules and structural requirements. For ventilation systems, there needs to be at least one inch but no more than three inches of space around those condenser units according to NSF/ANSI 7 standards. This spacing helps avoid problems like overheating components or wasting electricity unnecessarily. When it comes to electrical connections, different sized units need different setups. Most smaller undercounter appliances work fine on regular 20 amp circuits, but bigger walk-in units definitely need their own dedicated 30 amp line plus proper GFCI protection for safety reasons. The floor material is another important consideration too. Installers should look for non porous surfaces that can handle at least five hundred pounds per square foot without cracking or warping from moisture exposure over time.

Meeting health codes and industry standards for commercial refrigeration

The FDA Food Code 2022 mandates commercial refrigerators maintain ≤41°F (5°C) for cold storage, with digital thermometers calibrated quarterly. Door seals must pass the paper test (no slip when closed on a sheet) to ensure air retention. Third-party certifications like ENERGY STAR or UL Sanitation validate compliance during health inspections.

Balancing upfront price with long-term operating expenses

When looking at Total Cost of Ownership or TCO for equipment, we generally see about 40 to 50 percent going toward initial purchase costs, around 30 to 35 percent on day to day running expenses, and roughly 15 to 20 percent for upkeep and repairs. Most units consume somewhere between 2,500 and 7,000 kilowatt hours annually just sitting there doing their thing. To get a clearer picture of what something might cost over five years, folks often use this basic equation: take what was paid upfront, add all those operating costs, throw in maintenance money, factor in disposal costs, then subtract whatever residual value remains. Let's put some real numbers to this concept. Imagine buying a reach-in refrigerator for eight grand, paying about twelve hundred dollars each year just for electricity. Over time, that adds up to nearly twenty six thousand bucks total cost of ownership, which is actually sixty percent more than what was originally paid at the register. Smart shoppers should focus on appliances that can recoup their investment within three years max. Look for models featuring Energy Star certified compressors since these tend to save money long term. Also consider units with anti microbial coatings because they cut down on how often deep cleaning needs to happen, saving both time and resources.

FAQ

What are the key types of commercial refrigerators?

The main types include Reach-In Refrigerators, Walk-In Coolers, Undercounter Refrigerators, and Refrigerated Prep Tables, each catering to different operational needs and space considerations.

How do I choose the right commercial refrigerator for my business?

Consider factors like the type of food made frequently, your daily inventory turnover, and your kitchen's workflow and layout. The decision depends on your specific storage, space, and ergonomic needs.

What's the importance of energy efficiency in commercial refrigeration?

Energy-efficient refrigerators reduce your operational costs and have a lower environmental impact. Opt for models with high Energy Efficiency Ratios (EER) and ENERGY STAR certifications for savings.

Why are climate class ratings important for commercial fridges?

Climate class ratings determine the conditions a fridge can handle. Selecting the right rating ensures your refrigerator functions properly in your kitchen’s specific heat and humidity levels.

What should I consider during the installation of a commercial fridge?

Ensure proper ventilation, electrical setup, and adherence to floor weight capacities. This prevents overheating and ensures efficient operation, complying with rules and safety standards.

Table of Contents

-

Understanding Key Types of Commercial Refrigerators

- Reach-In Refrigerators: Ideal for High-Access Storage

- Walk-In Coolers: Maximizing Storage Capacity for Large Operations

- Undercounter Refrigerators: Space-Saving Solutions for Compact Kitchens

- Refrigerated Prep Tables: Streamlining Food Preparation Workflows

- Comparative Analysis of Commercial Refrigerator Types by Use Case

- Matching Refrigerator Type to Business Model and Operational Needs

- Sizing and Space Planning for Optimal Kitchen Integration

- Evaluating Performance Features and Energy Efficiency

- Installation, Compliance, and Total Cost of Ownership

-

FAQ

- What are the key types of commercial refrigerators?

- How do I choose the right commercial refrigerator for my business?

- What's the importance of energy efficiency in commercial refrigeration?

- Why are climate class ratings important for commercial fridges?

- What should I consider during the installation of a commercial fridge?