Temperature Stability: The Foundation of Drink Freshness in a Commercial Refrigerator

Why Consistent Cooling Is Critical for Drink Preservation

Beverage quality stays intact in commercial fridges when they keep things cool between about 34 and 38 degrees Fahrenheit. This range really helps slow down bacteria growth, maybe cutting it back around 70% compared to places where temps go up and down all day long. The stable temperature matters a lot for keeping drinks safe to eat and drink, plus it makes all the difference in how they taste and whether they stay fizzy. Just imagine what happens when the fridge gets even 2 degrees warmer or colder than it should be. Carbonated beverages lose about 15% of their CO2 retention under these conditions. That means customers end up with flat soda instead of the crisp, refreshing drink they expect from a good refrigerator setup.

How Commercial Refrigerator Maintains ±0.5°C Precision

When advanced compressors work together with digital thermostats, they keep things cool pretty consistently, usually staying within half a degree Celsius. The dual evaporator system basically creates separate cooling areas so different parts of the fridge can maintain their own temperature settings. And those doors? They're built with vacuum insulation that really helps stop outside heat from getting in. A recent study from last year found something interesting too: these premium units bounce back to ideal temps about three times quicker than regular models whenever someone keeps opening and closing the door. That means drinks and food stay at their best quality even when the fridge gets used a lot throughout the day.

Impact of Temperature Swings on Carbonation and Flavor

Fluctuations as small as 5°F can cause a 25% loss in carbonation within four hours, directly affecting sparkling drink quality. Non-carbonated beverages are equally vulnerable; cyclic temperature changes accelerate the breakdown of volatile organic compounds, with citrus-based drinks losing up to 40% of their aromatic profile under unstable conditions.

Comparison With Residential Units: A Data-Driven Analysis

| Metric | Commercial Refrigerator | Residential Unit |

|---|---|---|

| Temperature Precision | ±0.5°C | ±2°C |

| Recovery Speed | 8 minutes | 22 minutes |

| Annual Spoilage Rate | 2.1% | 6.8% |

Commercial units offer 3.2 times better temperature stability than residential models, reducing spoilage and cutting energy waste by 18% (Food Storage Journal 2023).

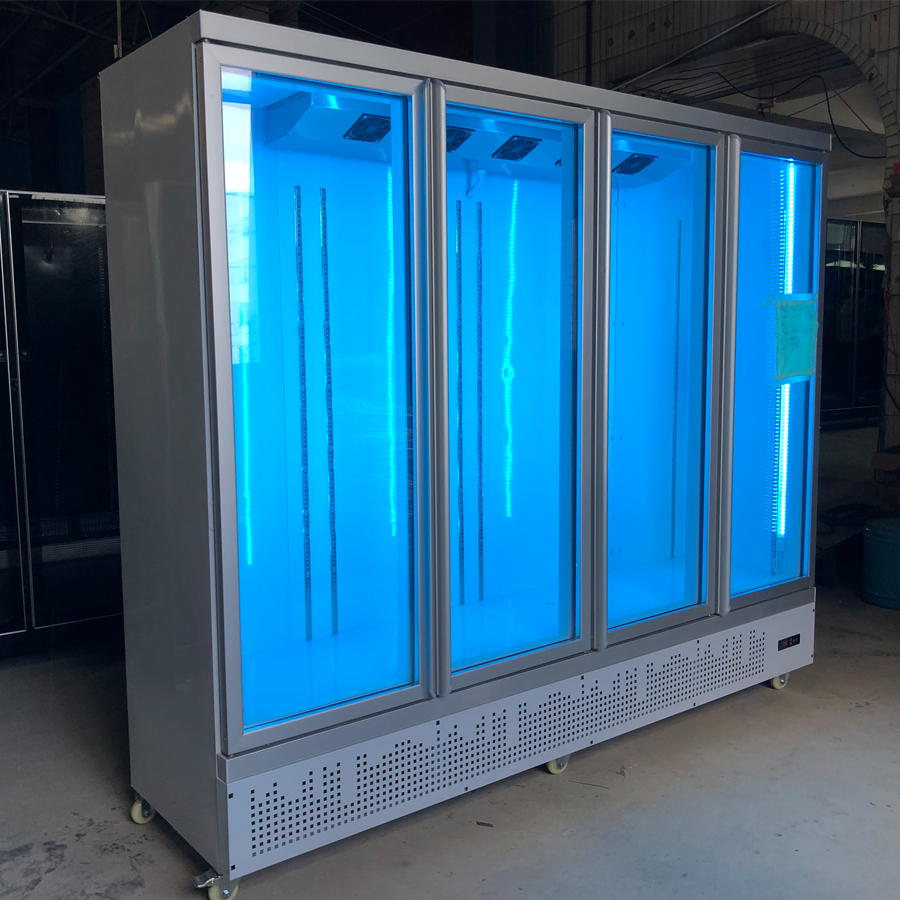

Advanced Airflow Design for Uniform Beverage Cooling in Commercial Refrigerator Systems

Uniform Circulation: Preventing Hot Spots in Beverage Storage

The engineered airflow systems keep things cool consistently throughout storage areas, maintaining temperatures within about half a degree Celsius difference between zones according to Food Preservation Journal from last year. Residential fridge models typically blow air in just one direction, but commercial units have those fancy multi zone fans creating an actual air curtain around drinks instead. These systems really help prevent those annoying hot spots that creep up between 4 and 6 degrees Celsius. Without proper airflow management, these temperature fluctuations can actually speed up how quickly flavors fade away in fizzy drinks, sometimes making them taste off after only about 40% less time than they should.

Evaporator Placement and Fan Velocity in Commercial Refrigerator Models

Putting evaporators in the right spot helps keep the cooling parts away from where bottles are stored, so direct airflow doesn't mess with their quality. When vertical coils are used together with those variable speed fans that run between 650 and 850 revolutions per minute, they spread out the cold air about 30 percent quicker than what we see in regular home systems. Some tests on 23 different commercial units found these setups reach nearly perfect temperature consistency at around 98%, while standard models only hit about 82%. These numbers come from the HVAC Efficiency Report published last year.

Case Study: Chain Restaurant Reduces Spoilage by 32% With Optimized Airflow

A 120-location restaurant chain upgraded to commercial refrigerators featuring:

- Triple-path air duct systems

- Humidity-compensating fan algorithms

- Thermal barrier door seals

Post-installation results over six months showed:

| Metric | Improvement | Timeframe | Source |

|---|---|---|---|

| Beverage spoilage | 32% reduction | 6 months | Chain Operations Report 2024 |

| Energy consumption | 19% decrease | Annual | |

| Service calls | 41% fewer | Q1-Q3 |

The improvements eliminated a previously observed 7°C temperature gap between top and bottom shelves, keeping carbonation loss in draft sodas below the 15% threshold defined by ISO 22000 Beverage Standards.

Humidity Control and Its Role in Preserving Drink Quality

How moisture levels influence bottle condensation and label integrity

Most commercial fridges keep humidity around 55-65% relative humidity (RH) to stop condensation from forming and keep those product labels looking good. When there's too much moisture in the air, water starts collecting on bottle surfaces. This makes brand logos hard to see, creates breeding grounds for bacteria, and actually makes the glue holding labels on weaker over time. On the flip side, if the fridge gets too dry (below 40% RH), paper labels start to dry out. They crack and curl at the edges, making products look unappealing on store shelves. Modern refrigeration units address these issues with vapor tight door seals and carefully controlled air circulation systems. These features maintain stable conditions inside, so labels stay readable and products don't get damaged before they reach customers.

Commercial refrigerator humidity sensors: Technology and calibration

Capacitive polymer sensors offer around 2% accuracy when it comes to tracking humidity levels, taking samples every five minutes throughout the day. What makes these sensors stand out is their ability to tweak fan speeds and control compressors automatically so they stay within desired parameters. When using two sensors together instead of just one, the system checks readings against each other as they happen, which cuts down on mistakes by roughly two thirds compared to systems with only a single sensor. Commercial grade equipment works differently from what we see in homes. These industrial models actually reset themselves during defrost periods, keeping measurements accurate even when temperatures fluctuate wildly. This means technicians don't have to constantly check and manually correct settings like they would with standard residential systems.

Smart Monitoring and Predictive Maintenance in Commercial Refrigerator Operations

IoT-Enabled Sensors for Real-Time Drink Storage Condition Tracking

Sensors connected to the internet track temperature changes down to 0.1 degrees Celsius, along with humidity levels and whether doors are opened or closed. These devices send updates every 15 seconds straight to online dashboards that managers can access from anywhere. When storing delicate drinks such as artisanal sodas or nitrogen-infused coffee, having immediate insight into warehouse conditions makes all the difference. A sudden spike in temperature might mean thousands of dollars worth of product going bad if not caught soon enough. The ability to spot problems early on keeps shelves stocked with fresh products rather than empty ones after spoilage occurs.

Alert Systems for Door Open Duration and Temperature Deviation

Today's commercial fridges come equipped with smart alert systems that let staff know if doors stay open past 90 seconds or if temps go over their limits by 1.5 degrees Celsius for half an hour straight. These alerts matter because leaving fridge doors open too long can actually bump up energy usage by about 18%. When someone forgets to close the door properly, the system kicks in with automatic load balancing that tweaks how hard the compressor works. This helps keep things stable inside, so drinks don't lose their fizz or taste weird after sitting around in fluctuating temperatures.

Case Study: Hotel Chain Cuts Maintenance Costs by 27% Using Predictive Analytics

One major hotel chain installed vibration sensors on around 1,700 refrigerators spread across their 240 locations worldwide. Looking at how compressors vibrate and matching these patterns against past breakdown data allowed the system to spot early signs of motor problems about 92 percent of the time. The best part? Hotel staff got nearly two weeks notice before any real issues happened. This proactive monitoring cut down on last minute fixes and saved roughly $86k each year in drinks that would have otherwise spoiled due to unnoticed cooling problems according to recent industry reports from 2023.

FAQ

Why is temperature stability important in commercial refrigerators?

Temperature stability is crucial because it slows down bacteria growth and retains beverage quality, ensuring drinks remain safe to consume and taste fresh.

How do commercial refrigerators maintain precise temperature control?

Advanced compressors and digital thermostats ensure temperature consistency, supported by dual evaporator systems and vacuum-insulated doors to prevent external heat infiltration.

What impact do temperature fluctuations have on beverages?

Temperature swings can significantly reduce carbonation and affect the aromatic profile of drinks, leading to flavor degradation.

How do commercial refrigerators differ from residential units?

Commercial refrigerators offer better temperature precision, faster recovery speed, and lower spoilage rates compared to residential models.

Table of Contents

- Temperature Stability: The Foundation of Drink Freshness in a Commercial Refrigerator

- Advanced Airflow Design for Uniform Beverage Cooling in Commercial Refrigerator Systems

- Humidity Control and Its Role in Preserving Drink Quality

- How moisture levels influence bottle condensation and label integrity

- Commercial refrigerator humidity sensors: Technology and calibration

- Smart Monitoring and Predictive Maintenance in Commercial Refrigerator Operations